Product Lifecycle Management (PLM) is the strategic process of managing a product’s entire journey, from its initial conception to its eventual disposal, covering development, manufacturing, and support along the way. This process provides a holistic approach to overseeing the people, data, and procedures involved in a product’s value chain.

On the technology side, PLM software serves as the digital foundation for centralizing all product information, integrating processes across globalized supply chains. This type of system ensures that everyone—from engineers to sales teams—works from a single source of truth.

PLM is critical for driving innovation in competitive markets, helping organizations with compliance and enabling transitions to new business models, such as product-as-a-service. It aligns complex corporate processes and helps companies bring high-quality products to market at lower costs and with greater agility.

Ultimately, Product Lifecycle Management acts as an essential business strategy for those seeking a competitive edge. It connects departments, breaks down data silos, and turns innovation into actionable insights that enable more assertive decision-making.

Follow us on the SoftExpert blog to learn about the five phases of product development and the main PLM use cases!

The Evolution of PLM: From CAD to Industry 4.0

The history of Product Lifecycle Management (PLM) is a story of technological adaptation: what began as a simple data management tool has evolved into the backbone of modern digitalized manufacturing. This progression has gone through four different generations, each representing a new level of complexity in product development.

PLM 1.0: Managing CAD Files

The earliest version of Product Lifecycle Management emerged from the challenge of handling Computer-Aided Design (CAD) files. These initial systems were called Product Data Management (PDM).

They primarily served as digital vaults focused on version control and design file security.

PLM 2.0: Supporting Collaboration and Globalization

In the 1990s, the pressures of globalization and outsourcing forced companies to expand PLM beyond engineering. This second generation added more layers of security and collaboration, introducing features such as quality planning, manufacturing, and compliance.

At this stage, the priority was to eliminate departmental silos. The main challenge, however, was that these systems required costly customizations. On top of that, their user experience (UX) was far from friendly.

PLM 3.0: Integration with the Supply Chain and Product Launch

Starting in the 2000s, PLM shifted its focus to managing the product launch process holistically. Product Lifecycle Management began incorporating early-stage processes such as innovation and requirements management.

During this period, efforts were also made to strengthen connections with later stages, particularly manufacturing and the supply chain.

This was an era when organizations commonly acquired new functionalities and integrated them into existing legacy platforms. The result was the creation of complex and sometimes fragmented systems.

PLM 4.0: the era of the digital thread, iot, and digital twins

PLM 4.0 is the latest iteration of this technology and typically includes cloud-native platforms, delivered as Software-as-a-Service (SaaS), with a focus on customers and the entire supply chain. It is designed to provide the foundation for the digital thread, a continuous flow of data that connects all stages of a product’s lifecycle.

The most modern product lifecycle management software enables collaboration across different areas and supports agile product development, reducing time-to-market. These systems centralize product, process, and supplier data, automating workflows to unify teams and routine operations.

An example of this approach is SoftExpert PLM, which offers real-time visibility into the product lifecycle, agile development, robust quality management, and AI-powered automation through Copilot. This is delivered via a modular, scalable, and secure platform.

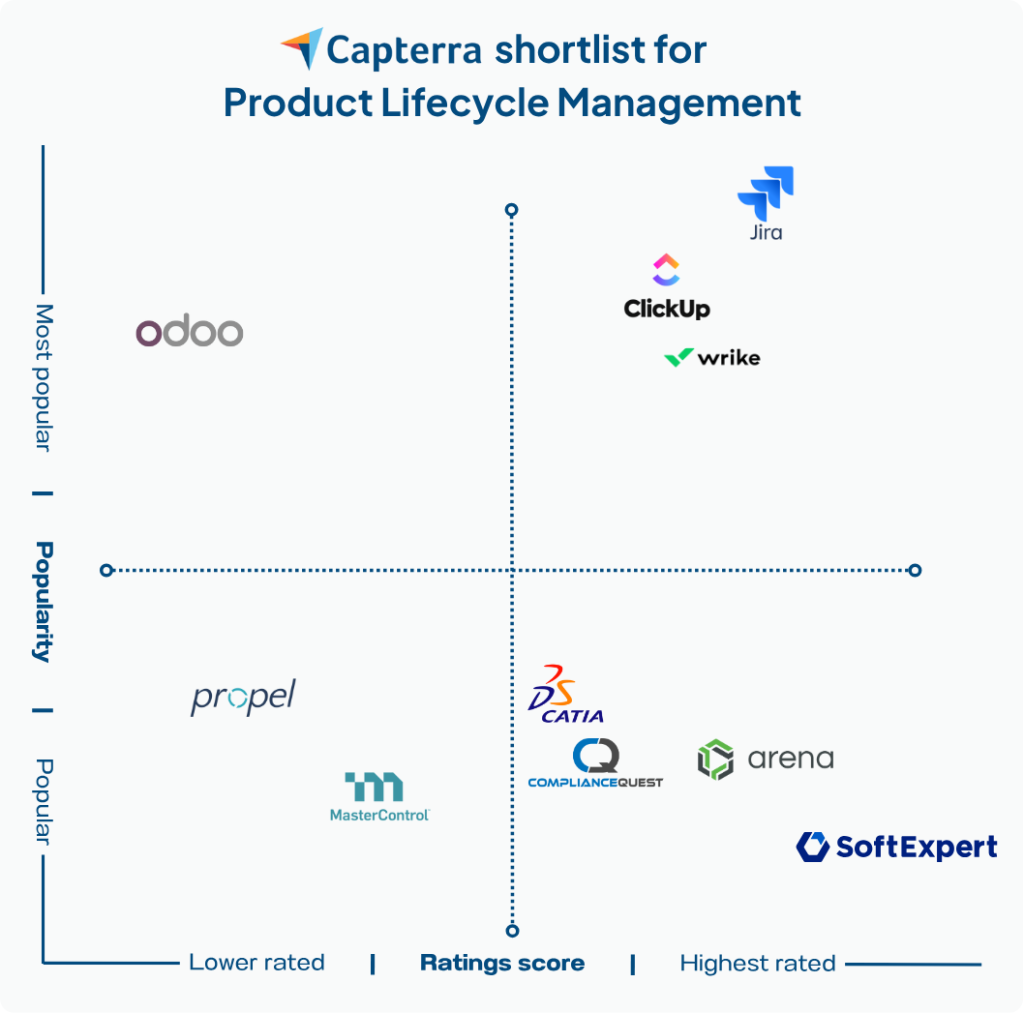

The platform was featured in the “Capterra 2025 Shortlist for Product Lifecycle Management”. SoftExpert PLM achieved the highest rating among the listed solutions, with an average score of 4.6/5.

What are the benefits of adopting a plm system?

Implementing a PLM system is a strategic investment that transforms how a company operates, creating a unified digital ecosystem. The result is tangible gains across all departments, from the shop floor to the boardroom.

By centralizing all product-related information, a PLM platform ensures seamless collaboration with full visibility into every stage of the product lifecycle.

These advantages have a direct impact on your company’s profitability. Organizations that successfully implement PLM typically experience the following benefits:

- Cost and time-to-market reduction. PLM software streamlines the development process, minimizes the need for physical prototypes, and eliminates errors early in the design phase. Entering the market faster gives your company more time to capture market share and respond to consumer trends.

- More innovative and higher-quality products. With a centralized repository for lessons learned and feedback, teams can improve designs and proactively address quality issues. By reducing administrative tasks, engineers have more time and resources to focus on innovation.

- Greater collaboration between teams and suppliers. A cloud-based PLM system provides secure, controlled access for internal teams and external suppliers. This prevents information silos and ensures everyone works with the most up-to-date data.

- Compliance assurance and risk reduction. Your organization can manage regulatory requirements and ensure products are designed and documented according to industry standards. This reduces the risk of non-compliance, which can lead to fines, recalls, and reputational damage.

- Sustainability and end-of-life management. PLM enables your company to design sustainable products from the start, considering factors such as material selection, energy efficiency, and recyclability. This proactive approach aligns with sustainability and compliance goals, following circular economy principles.

- Data-driven decision-making. Modern PLM systems integrate with real-time analytics tools, providing insights into product performance in the field. This allows managers to make proactive, well-informed decisions for future product iterations, maintenance, and development strategies.

Ultimately, the synergy of these six benefits creates a powerful multiplier effect, driving efficiency and fostering a culture of continuous improvement. The data-driven foundation provided by a PLM system paves the way for future innovations, ensuring your company’s long-term viability in an increasingly agile and competitive market.

Read more: Future trends in product lifecycle management (PLM)

What are the 5 phases of the product lifecycle?

Effectively managing a product’s journey requires a structured approach that breaks its lifecycle into clear, manageable stages. Understanding these phases is essential for better resource allocation and risk mitigation.

Here are the five most important stages of product development:

- Concept and design. The initial phase where ideas are generated, market needs are identified, and initial concepts are created. It involves brainstorming, feasibility studies, and defining the value proposition.

- Development. Prototyping and rigorous testing turn the concept into a tangible product. This stage focuses on validating the design, refining functionalities, and ensuring the product meets all required quality and performance standards.

- Production and launch. Once finalized, the product moves into large-scale manufacturing, transitioning from pilot tests to mass production. This phase culminates in the product launch and must be coordinated with marketing, sales, and distribution teams to ensure success.

- Service and support. After launch, the focus shifts to maintaining the product in the market through customer support and warranty management. This stage is vital for gathering user feedback, performing repairs, and ensuring customer satisfaction throughout the product’s operational life.

- End-of-life. The final phase involves managing the product’s retirement, including ending production, completing last sales, and providing long-term support. Decisions must also be made regarding parts replacement, service obligations, and product disposal or recycling.

The five phases of the product lifecycle present a complex challenge that impacts time-to-market, cost, and product quality. This is where Product Lifecycle Management (PLM) software becomes indispensable, as it provides the tools to manage each of these stages.

That’s what we’ll demonstrate in the following use cases.

What are the use cases of plm?

A product lifecycle management system acts as the central nervous system of modern product development. It connects dispersed teams and consolidates data into a cohesive digital thread.

Its practical applications span the entire organization, transforming how companies innovate, collaborate, and bring products to market. In this section, we’ll explore use cases that show how PLM moves from theory to delivering tangible value for your business.

Bill of materials (BOM) management

Effective BOM management forms the foundation for product development, ensuring consistency and accuracy throughout the lifecycle. A BOM allows teams to evaluate and implement changes efficiently while maintaining quality and regulatory compliance across the entire development process.

Quality assurance and compliance

PLM systems provide closed-loop quality management with real-time transparency and traceable information. This enables companies to ensure product compliance and track changes proactively, adapting quickly to global standards and customer requirements.

Collaboration and supply chain optimization

Product lifecycle management enables real-time collaboration with suppliers, allowing organizations to model sourcing scenarios and anticipate risks. This visibility and agility extend across the supply chain, helping reduce lead times, increase resilience, and align decisions with financial and sustainability goals.

Cost and profitability management

Integrated PLM solutions provide real-time expense tracking, helping teams anticipate financial impacts from the early stages of the development process. This unified view of costs allows for proactive adjustments, enabling profitability optimization throughout the entire product lifecycle.

Multidisciplinary collaboration in design

Modern product lifecycle management software eliminates barriers between mechanical, electrical, and software teams. They provide a unified digital environment where engineers can work in parallel, ensuring consistent data and accelerating development cycles.

Product development and portfolio management

Companies can define, monitor, and align product roadmaps with strategic business objectives. This ensures projects stay on schedule and can effectively respond to market needs.

Meanwhile, managers determine the introduction of new products and the demand for technical modifications.

Engineering data management and security

PLM centralizes design files, simulations, and documentation while ensuring controlled access and regulatory compliance. Security features such as data encryption and version tracking reduce risks while improving the operational efficiency of engineering teams.

Read more articles like this:

Conclusion

The field of product lifecycle management has evolved from a simple management tool into a critical strategic initiative for modern manufacturing. PLM provides the essential digital thread that connects all stages of a product’s journey, from initial concept to end-of-life.

The tangible effects of implementing PLM software are clear, delivering direct impacts on efficiency, innovation, and profitability. Companies gain significant advantages, including shorter time-to-market, reduced costs, greater compliance, and higher-quality products.

Adopting a modern PLM platform is no longer just an option but a critical investment to ensure competitive advantage and long-term business viability. It will pave the way for future innovations, allowing you to stand out in an increasingly agile and demanding market.

Embracing product lifecycle management is the decisive step to transform your product development process and lead your organization to operational excellence.

Looking for more efficiency and compliance in your operations? Our experts can help identify the best strategies for your company with SoftExpert solutions. Contact us today!

FAQ – Frequently asked questions about Product Lifecycle Management (PLM)

Lifecycle management is the strategic process of managing a product’s entire journey, from its initial conception to disposal. It involves holistically overseeing all people, data, and processes involved in the product’s value chain.

PLM stands for product lifecycle management. It is a strategic approach and a set of software solutions for managing all aspects of a product’s lifecycle.

A PLM system is the digital foundation for centralizing all product information, integrating processes across global supply chains. It ensures that all stakeholders work from a single source of truth.

The five phases are: concept and design, development, production and launch, service and support, and end-of-life. Each phase represents a distinct and manageable stage of the product journey, from the initial idea to disposal.

A PLM system works by centralizing all product data in a single, secure repository, creating a “single source of truth.” It integrates people, processes, and data, automating workflows and enabling real-time collaboration across departments and suppliers.

PDM (product data management) was the first generation of PLM, focused mainly on version control and CAD design file security. Modern PLM is much broader, managing the entire product lifecycle and integrating business processes beyond development.

Product development software refers to solutions that support the process of creating and launching new products by centralizing data and automating workflows. They provide real-time visibility, robust quality management, and agile development.